In my last post I said my circuit board path test resulted in an engraving that was 80% of the size it was supposed to be. That number didn't ring any bells at the time. Later that evening I was brushing my teeth and thought, "What's 72/90?" I grabbed my phone (my Sharp scientific calculator died years ago) and ran the numbers. The answer? 0.8!

So where did I get 72 and 90? I remembered reading somewhere recently that Inkscape (the SVG drawing program I'm processing the design with) works in "pixels" as its base unit of length. "Pixel" is short for "picture element". It's the smallest dot the computer can make on the screen. Which means it's pretty arbitrary. The actual length of a line 150 pixels long depends on the size of the monitor and the resolution the display is set to. Anyway, what I read said Inkscape assumes 90 pixels per inch.

Years ago when I worked in graphic design, monitors were smaller and video displays were lower resolution. Back then, 72dpi, dots per inch or really pixels per inch was the convention. So there're the 2 numbers that popped in my head. I wondered if there was some error in the software. Obviously not mine since I did a Java-only path that measures out correctly.

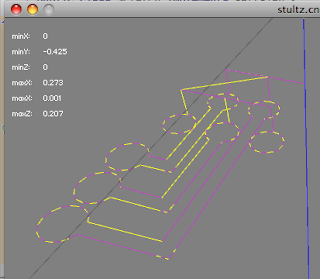

The GCode plug-in I'm using in Inkscape is written in Python which I know a little about. I couldn't find any factors for scaling hard-coded into the exporter. The plug-in asks Inkscape for the conversion factor. I set my document to inches and sure enough it returns 90 like the documentation said it would. I simply hard-coded 72 as the scale factor, exported the GCode again and my host software reported the proper extents.

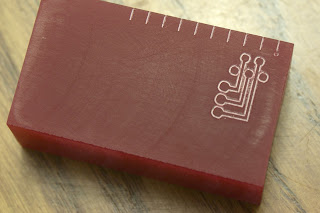

I ran the program and got this:

It's pretty hard to measure such a thing as this. Using my dial caliper and magnifying glass I took a couple of rough measurements. The PCB design software says the traces are "thin" or 0.016". I expanded the path to use as much room as possible (two adjacent circles nicely come together at a tangent) and the traces seem to be closer to 20 mils. The small pads for the DB-25 I measured somewhere around 60 mils. According to Inkscape the pads are... 60 mils. That's pretty cool.

I drilled a hole with my 1/32" drill bit, the smallest I have. There isn't much room around it. I definitely need a smaller bit. I might reshape the pads, make them rectangles, to give me more room to solder.

So it looks promising. My goal was to determine if I could isolate the paths and still leave enough copper to solder to and looks clear that will work. Really I should do another test on some real copper to check the isolation using the depth-of-cut I used on this test.

Ok, I just ran downstairs and did a test on a scrap perf board. The depth I used on the red piece was 10 mils. That didn't cut all the way through. I dropped down 5 more and it cut clean. According to a quick geometry check in QCad, the difference in width from a 10 mil deep cut to a 15 mil deep cut is 3.3 mils. I don't think that's significant, so I'm still feeling positive.

On more thing. You might notice the pad circles are not real, well, circular. I'm sure this is the effect of the backlash I'm totally ignoring at this point. I'll address that another day.